Eddy current testing, a non-destructive method based on electromagnetism, utilizes electromagnetic induction to identify discontinuities in conductive materials. In conventional eddy current testing, a specially designed coil energized with alternating current is positioned near the test surface, creating a dynamic magnetic field that induces eddy currents in the test part. Monitoring the variations in the phases and magnitude of these eddy currents reveals changes. Any alterations in the electrical conductivity or magnetic permeability of the test part, as well as the presence of discontinuities, lead to observable changes displayed on a screen for straightforward interpretation.

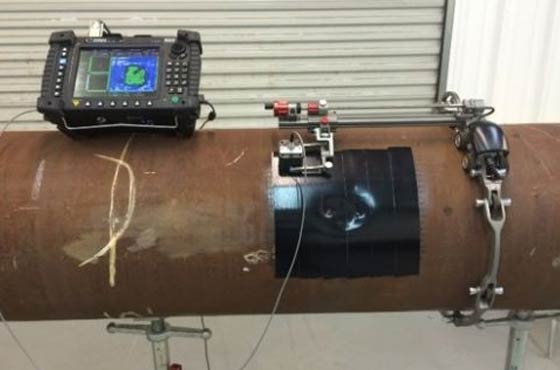

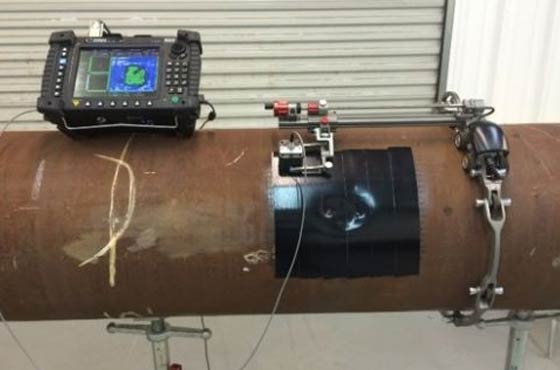

The phased array course provides the knowledge required to perform manual & encoded phased array testing on butt welds in Plates, Pipes and Pressure Vessels. The course covers theoretical and practical aspects on phased array application, its advantages and limitations. The course also covers the requirements for application of phased array as per code requirements. To impart adequate understanding for onsite application, our training is done using all necessary accessories such as calibration blocks, validation samples, encoder, scanners for different size applications, etc.

For this course, we strongly recommend participants possess knowledge in UT weld examination as Level II. At the end of the course, examination shall be conducted. The training programme shall be conducted by experienced PAUT practitioners and academic professionals who have been working in the application of PAUT.

The phased array course provides the knowledge required to perform manual & encoded phased array testing on butt welds in Plates, Pipes and Pressure Vessels. The course covers theoretical and practical aspects on phased array application, its advantages and limitations. The course also covers the requirements for application of phased array as per code requirements. To impart adequate understanding for onsite application, our training is done using all necessary accessories such as calibration blocks, validation samples, encoder, scanners for different size applications, etc.

For this course, we strongly recommend participants possess knowledge in UT weld examination as Level II. At the end of the course, examination shall be conducted. The training programme shall be conducted by experienced PAUT practitioners and academic professionals who have been working in the application of PAUT.